A Group priority for more than 10 years, GERGONNE has invested heavily to become a key player in the health and medical market as a medical adhesive tapes manufacturer.

ISO 13485 certified since 2012 (current certification body: BSI) and with a dedicated sales team, the company has the best production facilities for the healthcare sector worldwide.

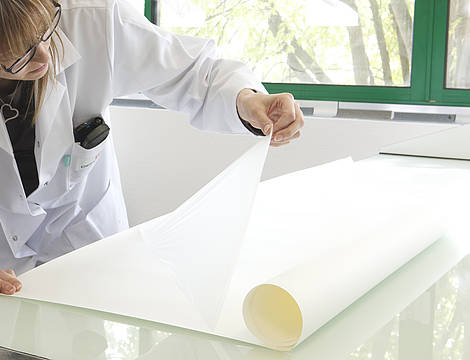

As a cleanroom medical adhesive tapes converter and with nearly 2000m² of ISO-8 clean rooms, GERGONNE offers its customers a continuous and complete manufacturing process in ISO-8 controlled atmosphere: coating, web die-cutting, printing, rotary die-cutting and packaging. Objective: to guarantee the best manufacturing standards and maximum safety for the patient during the final use of the products.

Expert in medical adhesive tapes converting, GERGONNE masters:

- the sourcing of materials meeting the requirements of the medical sector,

- the formulation of adhesive masses to bond to the skin (medical grade adhesive for skin),

- the two key processes (coating and rotary cutting) for the manufacture of adhesive tapes medical devices

As one of the very few fully vertically integrated players (formulation, coating, die cutting, packaging, sterilization management, regulatory affairs), GERGONNE is able to supply the medical market with raw materials, semi-finished products or finished products, depending on the needs expressed by its customers.

Besides the possibility of developing specific materials, GERGONNE, as a medical adhesive tape manufacturer, also has a range of standard medical grade adhesive tapes. These adhesive tapes products are grouped within the ADHECARE range which presents acrylic adhesive solution, medical grade silicone gel (atraumatic removal) and medical polyurethane films.

Discover our flagship solutions

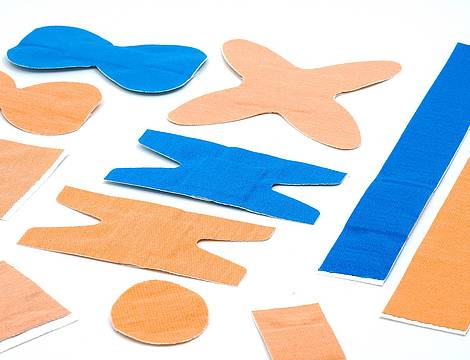

Die-cut components

Medical devices

Matières adhésives transformateurs

Adhesive materials for converters