For markets such as automotive electronics, sensors or electrical/electronic components in general, housing ventilation is a major issue.

The functioning of electrical or electronic components generates heat and an increase in pressure inside the housing.

This overpressure and heat must be evacuated efficiently, to avoid serious damage to the components themselves or to the housing gaskets.

Each year, GERGONNE manufactures several million ePTFE venting membranes and groups its standard solutions within the GERGOVENT range.

By carrying out tests in our laboratory, we know how to select the venting membranes most suitable for the market's needs and control their performance (air flow rate, MVTR, water intrusion pressure, climatic and thermal cycle, etc.).

The venting membranes proposed by GERGONNE have been designed to respond to the problem of overpressure and condensation, while also guaranteeing the absence of water or dust intrusion (from the outside environment to the inside of the case).

The ePTFE venting membranes of the GERGOVENT range improve the life of electronic components and increase their reliability.

Our GERGOVENT adhesive venting membranes are certified PFOA-free (Perfluorooctanoic Acid) and respond to various issues such as:

Our ePTFE venting membranes are used, for example, for automotive lighting applications (front and rear lights), electronic computers/cards, cameras, and small electric motors (e.g. window regulator motor).

GERGONNE has developed a new venting membrane (VM16). Its design makes it even more resistant to difficult conditions.

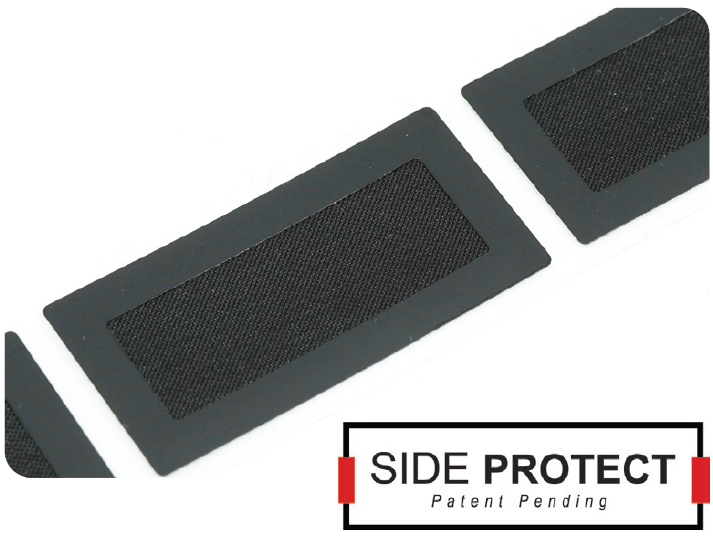

Thanks to the Side Protect technology (patent pending), our ePTFE VM16 ventilation membranes provide excellent adhesion and are even more resistant to water pressure.